Mass timber is transforming how we build, offering a sustainable, efficient alternative to concrete and steel. From reducing carbon emissions and material waste to accelerating project timelines and enhancing indoor air quality, it delivers environmental, operational, and wellness benefits that position it as a truly transformative building method.

What is Mass Timber?

Mass timber refers to a category of framing styles characterized by the use of large, engineered wood panels, often paired with engineered wood columns and beams. These structural elements work together to create strong, efficient structural framing systems. Common materials include cross-laminated timber (CLT) for floors and walls, and glue-laminated timber (glulam) for beams and supports. While CLT and mass timber construction are continuing to accelerate in North America, CLT remains a newer product in the industry, with many lessons still being learned as its popularity grows.

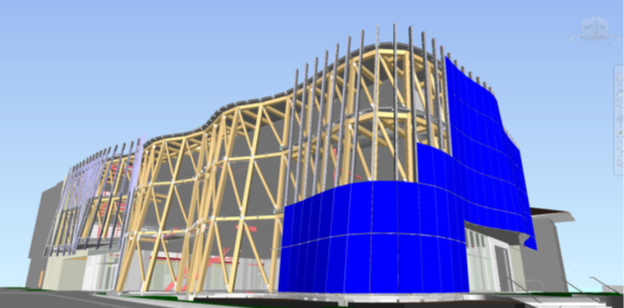

Hensel Phelps recently completed the Caltech Resnick Sustainability Center (RSC), which features a mass timber structural grid shell. Comprised of glulam timber beams and columns, the shell extends from level 1 to the roof and is visible throughout the building’s north and west common spaces. CLT wood decking is utilized throughout the north and west perimeters of the building. Hensel Phelps engaged a curtain wall consultant and mass timber trade partners to discuss the detailing associated with this scope. Throughout design and construction, the team learned valuable lessons related to fire protection, water mitigation, fabrication and installation of mass timber components.

FIRE PROTECTION

Fire safety is an inherent concern when building with wood. However, mass timber performs well in fire, due largely in part to the size and density of mass timber members. While common stick-frame structures use small pieces of lumber that are prone to burn easily, cross-laminated timber is produced by compressing layers of dimension lumber and the resulting large, solid piece of wood is difficult to ignite. It also burns at a known rate, and the resulting char on the outer layers of wood protects the critical inner layers, ensuring structural integrity for the duration required. This allows mass timber products to be left exposed and still achieve a fire-resistant rating.

The RSC project team worked closely with the design team to achieve the required fire ratings while maintaining constructability and the budget. Most of the wood-to-wood connections used concealed plates and fasteners covered by wood plugs, eliminating the need for steel fireproofing. The team also worked closely with a third-party vendor to provide an Engineering Judgement for intumescent sealant at more complex mass timber connections.

MOISTURE MITIGATION

A key to a mass timber structure’s durability is keeping it dry. While the mass timber components of the RSC were ultimately fully enclosed by the exterior skin, the team developed a temporary protection plan to prevent water instruction and mold prior to building dry-in. Measures included applying a protective undercoat to all wood members at the fabrication facility prior to shipping to protect the wood from UV degradation and moisture absorption. This was reapplied as needed throughout construction when the wood was field-cut, sanded or repaired. Components were also individually wrapped using plastic-coated paper covering, which was maintained throughout construction. Just-in-time delivery minimized on-site storage and moisture exposure risks and daily inspection of all mass timber members prevented damage from standing moisture.

FABRICATION

The geometry of the exterior grid shell on the RSC presented challenges in accommodating structural requirements, architectural appearance, constructability possibilities and fire protection constraints. 3D modeling and detailing provided the mass timber design-build contractor, WS Klem, with precise work points for layout of glulam columns and CLT edge geometry. After fine tuning placement and expectation for tolerances, the team modeled the glulam beams and fabricated hardware of thousands of one-off components produced by multiple suppliers.

Once models were coordinated and shop drawings were reviewed and approved, the team began producing hundreds of glulam and CLT panels. Each beam, column, CLT panel and piece of hardware was unique, requiring extensive quality control to minimize the possibly for field modifications. The mass timber fabricator test-fit all wood-to-wood and steel connections at their facility before shipping to the jobsite, enabling adjustments to be made in the shop and avoiding installation delays.

INSTALLATION

The mass timber and glazing scopes were both prefabricated offsite, meaning everything needed to be erected to the tolerances that were agreed to in the modeling phase. Layout information was provided to the field team to ensure the placement of the mass timber would align with those agreed work points. The diligence in preconstruction and quality control paid off and the system was erected with zero rework in the field, despite a highly complex, curved façade with a composite structure consisting of mass timber, concrete and steel.

Utilization of design-assist trade partners contributed greatly to the success of the project. During the procurement of the mass timber components, Hensel Phelps integrated WS Klem into the design-build team. This allowed Hensel Phelps to visit key suppliers to better understand the supply chain and ensure the implementation of quality control measures.

The success of the RSC building highlights the possibilities and opportunities of mass timber. With a few additional considerations from traditional steel and concrete, mass timber is a viable and appealing solution to a more sustainable future in design and construction.