About the Project

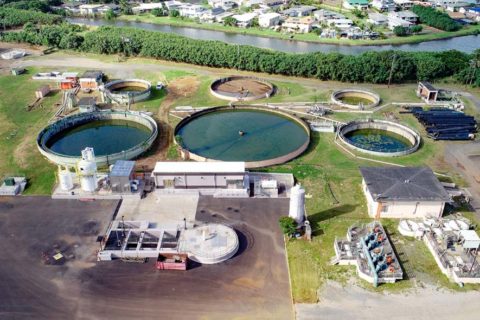

The Andrews Federal Center Bus Operations and Maintenance Facility project included the design and construction of two buildings in support of the Washington Metropolitan Area Transit Authority’s (WMATA) mixed fleet of transit vehicles. Constructed on 35 acres of land, the new 335,000 SF complex includes a Bus Operating Garage, a Bus Transportation Operations Facility, a Fuel/Wash Building, a Heavy Repair and Overhaul (HR&O) Facility, a Warehouse, a Service Vehicle Building, Bus Engineering, a Guard House, and Pedestrian Bridge. The Bus Operations and Maintenance Facility supports a 175 bus fleet (20% of which would be articulated buses) and operates 24/7.

The HR&O Facility supports the entire WMATA fleet of 1,600 buses and operates eight hours a day, five days a week. The Bus Operations and Maintenance Facility includes maintenance, operations, fuel, wash, bus parking, and employee/visitor parking. The HR&O Facility includes bus rehabilitation bays and support spaces (including body repair and paint booths), central warehouse, non-revenue vehicle maintenance, bus engineering, and employee/visitor parking.

“WMATA and Hensel Phelps have a long history and throughout the Andrews Federal Center Bus Garage project, they have reinforced their track record of delivering a high quality and cost-effective project. Hensel Phelps established a culture of complete transparency with WMATA and maintained our involvement from the beginning of the project to completion.”

– NORIE CALVERT, WMATA

Challenge

Maintenance of Equipment

During construction of the project, WMATA recognized a need to provide their employees an easy and visible way to manage and maintain the individual pieces of equipment in the facility. With hundreds of pieces of equipment housed across eight facilities, it was a challenge to tag and organize each piece of equipment.

Solution

Smart Asset Management

Through Hensel Phelps’ Facility Services, WMATA implemented COBie—a QR-based asset management system—on every piece of equipment. COBie allowed WMATA mechanics to scan a code placed on equipment with a smart phone, which would retrieve the piece of equipment’s replacement parts and price, O&M manual, and the warranty of the item, among other information. In addition, the team incorporated the QR codes into the Building Information Model (BIM) to allow for cross-referencing between WMATA’s Maximo Computerized Maintenance Management Software (CMMS) system and the Revit model. Hensel Phelps also demonstrated how COBie could be linked to the Revit model, enabling users to “fly” through a 4D model of the facility to locate a specific piece of equipment.

Result

Implementation on Future Projects

WMATA was so pleased with the solution that they will be implementing it in future builds and retrofitting current bus garages with the system.

Awards

2019

- Engineering News Record Mid Atlantic Best Projects: Award of Merit, Airport/Transit

- Associated General Contractors of Washington D.C. Washington Contractor Award, Highway, Transit, Bridge (Over $100M)

- Washington Building Congress Craftsmanship Award, Power Generation, Distribution, and Switchgear (Awarded to design-build partner Mona Electric Group)

- Washington Building Congress Craftsmanship Award, Special Systems (Awarded to design-build partner Mona Electric Group)

Related Projects

-

-

Infrastructure + Transportation project

National Western Center Horizontal Integrated Contractor Learn More -

Infrastructure + Transportation project

Valley Metro Operations and Maintenance Center Expansion Learn More -

-

-