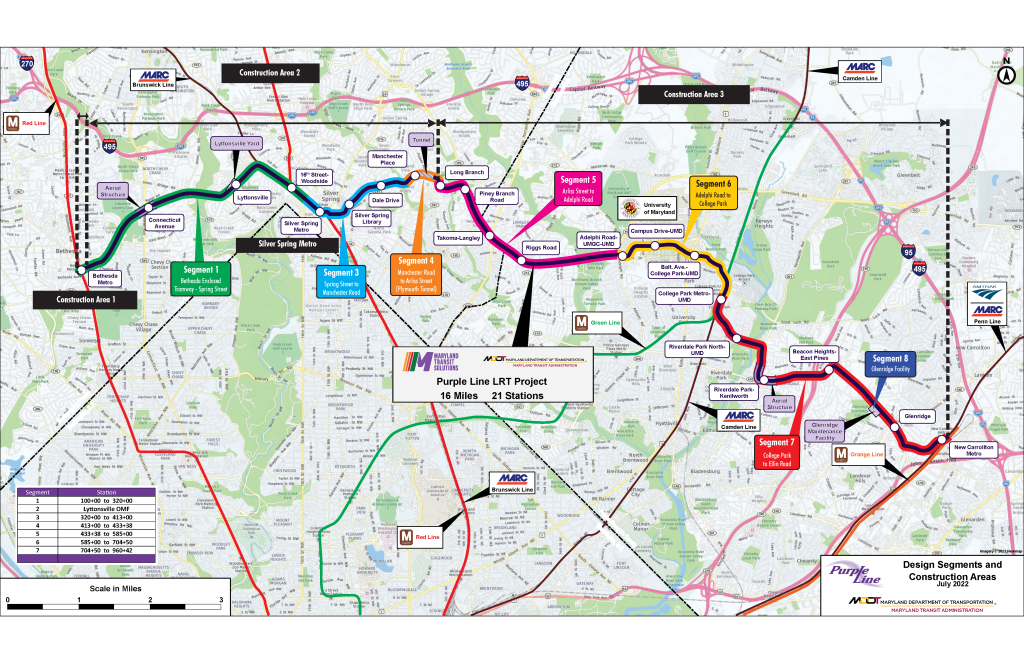

The Purple Line Light Rail project is a 16.2-mile-long light rail transitway that extends from Bethesda in Montgomery County to New Carrollton in Prince George’s County. It will provide direct connections to four branches of the WMATA Metrorail system, as well as all three Maryland Area Regional Commuter (MARC) rail lines and Amtrak’s Northeast Corridor at New Carrollton. The transitway will be largely at-grade with one short tunnel section, three sections elevated on structures, and several bridge structures. The transitway will operate mainly in dedicated or exclusive lanes, serving five major activity centers just north of Washington, DC.

This project is being delivered under a P3 contracting method in partnership with the MDOT MTA. Hensel Phelps is subcontracted under the design-builder to construct 15 simple stations, six complex stations, and one maintenance facility.

Due to the project’s logistically challenging 16-mile length, our project team has developed numerous strategies to manage staff across all project points, emphasizing the safety of our employees and surrounding pedestrians.

Project Management

With 21 stations spread out along the 16-mile light rail, the General Contractor/Owner, Maryland Transit Solutions (MTS), has broken up the project into three separate areas. Hensel Phelps aligned our project management strategy with MTS by assigning a project superintendent to areas one and two and another project superintendent to area three. Hensel Phelps has further divided these areas into 22-point phases. Each point phase of the project is thought of as its own separate project and is staffed with a field engineer and an area superintendent. Each location also has its own Emergency Action Plan, which locates designated rally points including the closest hospital located to each of the stations. Because each location on the project is thought of as its own separate project, the project management team has a direct line of communication with the staff on each point phase. This provides an extra layer of safety and efficiency when constructing this extensive project.

Logistics Management and Technology in Communication

The logistics management process of the Purple Line projects falls into three categories: driving, material handling and public exposure. The team prioritized mitigating risks that could potentially result from transporting personnel and materials across this 16-mile-long project, as well as the risks associated with constructing around heavy pedestrian footpaths including on an active college campus.

The logistics management process begins at the end of each day when the general foreman and the foreman discuss the progress of the project and what materials and staff are needed for the next day. Each morning, the craft arrives at the project’s laydown area where all bulk materials, vehicles, tools, equipment, fuel containers and extra barricades for public exposure are stored. Once the trucks are loaded up, the driver reviews the site utilization plans and determines which project sites they need to go to that day.

Hensel Phelps leveraged technology to ensure constant communication among all team members across all project point phases. The project team created a jobsite orientation sticker with a QR code that scans to bring up immediate resources including an emergency contact list, a safety suggestion submittal page and safety documentation reviewal and submission forms. The team implemented various QR codes for efficiency and real-time documentation of equipment inspections, trench inspections, quarterly inspections, the confined space log and more. The team also uses Team-Up for delivery coordination and is beta-testing SafetyConnect features, including a mass communication platform and digital hot work permits.

Transporting Equipment and Personnel Across a 16-mile Jobsite

Driving across the light rail alignment to the different work areas is an inevitable aspect of the Purple Line project. The team recognized a potential risk in safely transporting personnel and equipment to perform the work in temporary traffic control plans within the varying neighborhoods and downtown settings. To mitigate this risk, the team invested in a Dodge 5500 stake body truck with a lift gate for the transportation of bigger materials. Upon arrival, the team updated the truck with rear and side cameras, blind spot detection, a new head unit that utilizes CarPlay and essential Federal DOT-required signage and lights. The team purchased truck caps for the jobsite trucks to lock and protect cargo. Each jobsite truck was also equipped with dash cameras, CarPlay monitors, blind spot mirrors, a “Go-Bag” containing an OSHA inspection and crisis kit, a trauma kit and a packet of additional resources. The project has 29 fleet vehicles including cars, vans, trucks and state-body pick-up trucks used for transporting bulk materials. The drivers of these vehicles consist of craft and staff employees. All drivers are required to complete numerous driver safety trainings including a driver acknowledgment form, the Hensel Phelps Defensive Driver and Driver Commitment Training and the SMITH system driver training. This is just another way Hensel Phelps manages our logistics from a safety perspective by ensuring all drivers have the appropriate training to prevent vehicle accidents.

Protecting the Safety of Pedestrians on an Active College Campus

In addition to the six complex stations and 15 simple stations, the Purple Line will serve the residential communities, commercial districts and institutional establishments. These stations fall between major activity centers, including four stations serving the University of Maryland with its approximately 40,700 students and 14,500 employees and visitors a year. By 2030, the project is expected to attract over 60,000 daily boardings, with over one-third expected to use Metrorail and/or MARC services for some part of their trip.

The Purple Line is designed to transform the campus of the University of Maryland to provide students, faculty and visitors direct access to the campus. There are four stations integrated within the university’s campus, with two miles of light rail tracks that pass through it. Hensel Phelps is dedicated to protecting the safety of pedestrians and staff on all jobsites. The project team on the Purple Line is extensively trained on public hazard assessment and control measures, MUTCD standards, maintenance of traffic and traffic control plans. Before the project team mobilizes on the stations, Hensel Phelps sends out a team to evaluate the spaces to see where the team can go above and beyond to ensure that the public doesn’t interface with the work area and that the work does not interfere with the public.

On this invasive project, public safety was one of the highest priorities of the project team. Hensel Phelps logs a daily public hazard analysis to ensure the team manages hazards and keeps the public out of construction zones. The site-specific public hazard analysis correlates with the superintendent’s site-specific utilization plans, which begin with a daily walk in the morning to ensure those daily controls are in place and are followed up at the end of the day to document any potential hazards that could impact public safety.

Assuring that students, faculty and project staff return home safe each day is a top priority for the Hensel Phelps team. Through our innovative strategies for safety utilized on the Purple Line project, there have been 71,054 work hours to date with zero recordable safety incidents.